loading

| Size: | |

|---|---|

| Heating Jacket: | |

| Speed Regulation: | |

| Availability: | |

| Quantity: | |

SCH

RELA

SCH

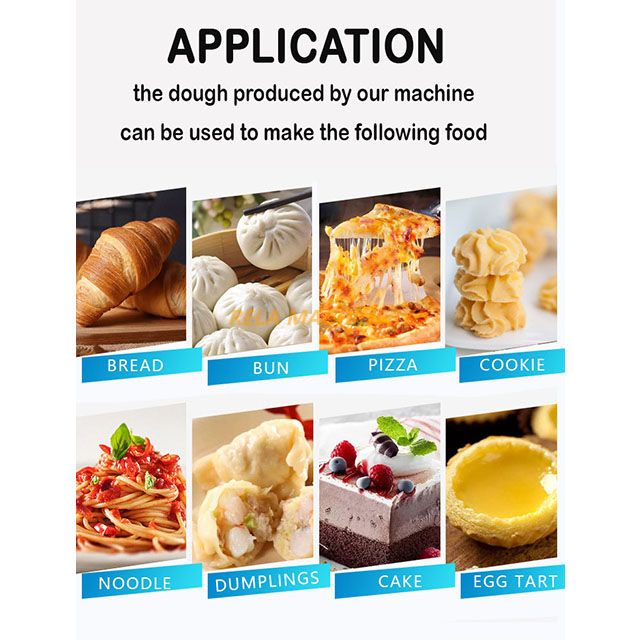

Double Z-arm mixer is designed for mixing of tough stuffing in the food processing plants and in bakeries. It is ideal for dough mixing and other thick and heavy stuffing.

Double Z-arm mixer is designed for mixing of tough stuffing in the food processing plants and in bakeries. It is ideal for dough mixing and other thick and heavy stuffing.

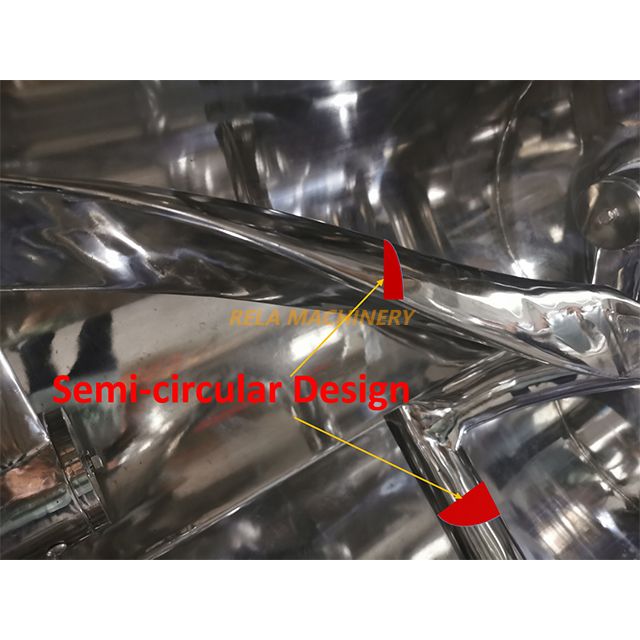

Mixing System:

Mixing system consists of two sigma (Z) shaped arms placed in

The mixer U bowl.

The casting arms are semi-circular designed to reduce the resistance and pressure during the

mixing process.

Two arms moves towards each other, providing better kneading effect and saving working time

Loading & Unloading:

The top lid can be fully unfolded by cylinder for loading. On the top lid, there is a small opening for liquid or additive filling.

Unloading of the stuffing is executed by electric tilting of the mixer bowl. This type of unloading system provides easy and quick emptying.

Construction:

The supporting frame is made of carbon steel with paint. The contact part of the mixer is made of stainless steel. The construction of the machine provides easy and safe service and maintenance and meets the highest

hygienic norms for food processing. Simple and stable welded stainless construction provides long life of the machine.

Control Unit:

-Simple control panel with digital display provides easy service of the machine.

-More powerful motor and reducer ensure the long machine life.

-All electrical components are placed inside the machine.

Optional Items:

-Jacket for heating or cooling;

-Inverter for speed regulation

Mixing System:

Mixing system consists of two sigma (Z) shaped arms placed in

The mixer U bowl.

The casting arms are semi-circular designed to reduce the resistance and pressure during the

mixing process.

Two arms moves towards each other, providing better kneading effect and saving working time

Loading & Unloading:

The top lid can be fully unfolded by cylinder for loading. On the top lid, there is a small opening for liquid or additive filling.

Unloading of the stuffing is executed by electric tilting of the mixer bowl. This type of unloading system provides easy and quick emptying.

Construction:

The supporting frame is made of carbon steel with paint. The contact part of the mixer is made of stainless steel. The construction of the machine provides easy and safe service and maintenance and meets the highest

hygienic norms for food processing. Simple and stable welded stainless construction provides long life of the machine.

Control Unit:

-Simple control panel with digital display provides easy service of the machine.

-More powerful motor and reducer ensure the long machine life.

-All electrical components are placed inside the machine.

Optional Items:

-Jacket for heating or cooling;

-Inverter for speed regulation

Model | Full Volume | Working Volume | Max. Loading Capacity | Stirring Motor | Unloading Motor | Weight |

SCH-100 | 100L | 40L-60L | 50KG | 5.5KW | 0.75KW | 800KG |

SCH-200 | 200L | 80L-120L | 100KG | 7.5KW | 1.1KW | 950KG |

SCH-300 | 300L | 120L-180L | 150KG | 11KW | 1.5KW | 1100KG |

SCH-400 | 400L | 160L-240L | 200KG | 15KW | 2.2KW | 1300KG |

SCH-600 | 600L | 240L-360L | 300KG | 18.5KW | 3KW | 1750KG |

SCH-800 | 800L | 320L-480L | 400KG | 30KW | 4KW | 2100KG |

Model | Full Volume | Working Volume | Max. Loading Capacity | Stirring Motor | Unloading Motor | Weight |

SCH-100 | 100L | 40L-60L | 50KG | 5.5KW | 0.75KW | 800KG |

SCH-200 | 200L | 80L-120L | 100KG | 7.5KW | 1.1KW | 950KG |

SCH-300 | 300L | 120L-180L | 150KG | 11KW | 1.5KW | 1100KG |

SCH-400 | 400L | 160L-240L | 200KG | 15KW | 2.2KW | 1300KG |

SCH-600 | 600L | 240L-360L | 300KG | 18.5KW | 3KW | 1750KG |

SCH-800 | 800L | 320L-480L | 400KG | 30KW | 4KW | 2100KG |

No. 108, huishan road, huishan district, wuxi, jiangsu,china

+86 13771600869