loading

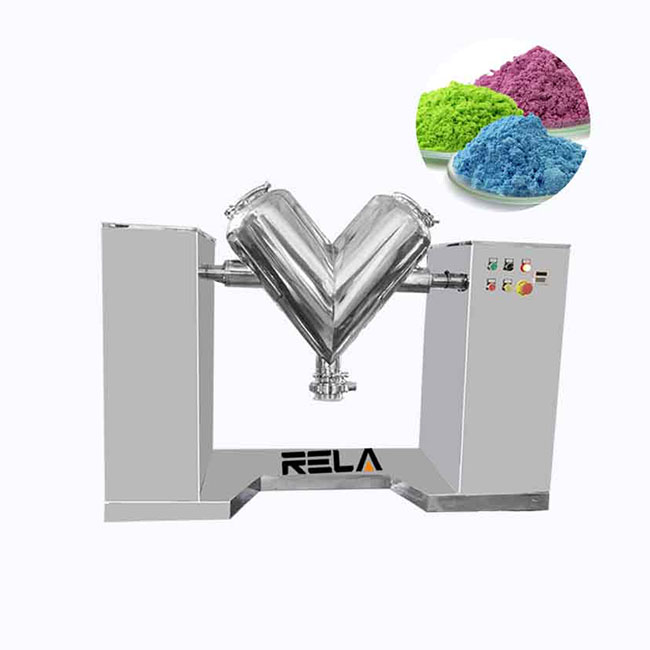

RELA V Cone Blenders are used for the drying blending of free flowing solid (powder, granule, etc.) in Pharmaceutical Industry, Foodstuff Industry, Spice Industry, Chemical Industry, etc.

RELA V Cone Blenders are used for the drying blending of free flowing solid (powder, granule, etc.) in Pharmaceutical Industry, Foodstuff Industry, Spice Industry, Chemical Industry, etc.

The materials being blended are loaded from top ports. The loading factor is 40%-60%. The materials being blended in these units can vary in bulk density and in percentage of the total mixture. V shell gets rotation under the driven of motor-reducer. Materials being blended are constantly being split and intermixed as the shell rotates. Normal cycle times are typically in the range of 15 minutes, however can be less depending on the difficulty of blending.

The materials being blended are loaded from top ports. The loading factor is 40%-60%. The materials being blended in these units can vary in bulk density and in percentage of the total mixture. V shell gets rotation under the driven of motor-reducer. Materials being blended are constantly being split and intermixed as the shell rotates. Normal cycle times are typically in the range of 15 minutes, however can be less depending on the difficulty of blending.

Suitable for bulk densities up to 0.6x103kg/m3

MOC SS304; supporting frame by Carbon Steel

Mirror polished for both interior and exterior

Hinged charging port

Manually-operated butterfly discharge valve

Fully integrated motors and controls

Suitable for bulk densities up to 0.6x103kg/m3

MOC SS304; supporting frame by Carbon Steel

Mirror polished for both interior and exterior

Hinged charging port

Manually-operated butterfly discharge valve

Fully integrated motors and controls

Higher power for handling higher bulk densities

MOC SS316L; All Stainless Steel construction

Matte polishing

Intensifying bar for deagglomeration

Safety railings

Explosion-proof; special voltage/frequency motor

PLC & HMI control; VFD for speed control

Vacuum Loading System

Higher power for handling higher bulk densities

MOC SS316L; All Stainless Steel construction

Matte polishing

Intensifying bar for deagglomeration

Safety railings

Explosion-proof; special voltage/frequency motor

PLC & HMI control; VFD for speed control

Vacuum Loading System

VCB Blender | Full Holding | Working Capacity | Power | Speed | *Overall Dimensions (mm) | *Weight | |||||||

Model | Liters | Cu. Ft. | Liters | Cu. Ft. | KW | RPM | L | W1 | W2 | H1 | H2 | H3 | KG |

VCB-50 | 50 | 1.77 | 25 | 0.885 | 0.55 |

12 | 1300 | 500 | 700 | 550 | 1200 | 1400 | 200 |

VCB-100 | 100 | 3.53 | 50 | 1.77 | 1.1 | 1750 | 600 | 1100 | 550 | 1500 | 1700 | 230 | |

VCB-150 | 150 | 5.3 | 75 | 2.65 | 1.1 | 1800 | 750 | 1200 | 550 | 1600 | 1800 | 250 | |

VCB-180 | 180 | 6.35 | 90 | 3.175 | 1.1 | 1900 | 800 | 1250 | 550 | 1800 | 1900 | 280 | |

VCB-300 | 300 | 10.6 | 150 | 5.3 | 1.1 | 2000 | 850 | 1350 | 550 | 1900 | 2050 | 380 | |

VCB-500 | 500 | 17.7 | 250 | 8.85 | 2.2 | 2400 | 950 | 1500 | 550 | 2080 | 2300 | 550 | |

VCB-1000 | 1000 | 35.3 | 500 | 17.7 | 4 | 2900 | 1300 | 1750 | 550 | 2200 | 2600 | 700 | |

VCB-1500 | 1500 | 53 | 750 | 26.5 | 4 | 3200 | 1400 | 2030 | 550 | 2580 | 2950 | 900 | |

VCB-2000 | 2000 | 70.6 | 1000 | 35.3 | 7.5 | 3550 | 1650 | 2300 | 550 | 2750 | 3200 | 1500 | |

VCB-2500 | 2500 | 88.25 | 1250 | 44.125 | 7.5 | 4000 | 1800 | 2450 | 550 | 2850 | 3500 | 1800 | |

VCB-3000 | 3000 | 106 | 1500 | 53 | 7.5 | 7.8 | 4400 | 1900 | 2600 | 550 | 3050 | 3600 | 2200 |

VCB-4000 | 4000 | 141.2 | 2000 | 70.6 | 11 | 7.8 | 4500 | 2000 | 2800 | 550 | 3500 | 4200 | 2800 |

*The data are estimated for reference only. (1L=0.0353cu.ft.; 1cu.ft.=28.3L)

VCB Blender | Full Holding | Working Capacity | Power | Speed | *Overall Dimensions (mm) | *Weight | |||||||

Model | Liters | Cu. Ft. | Liters | Cu. Ft. | KW | RPM | L | W1 | W2 | H1 | H2 | H3 | KG |

VCB-50 | 50 | 1.77 | 25 | 0.885 | 0.55 |

12 | 1300 | 500 | 700 | 550 | 1200 | 1400 | 200 |

VCB-100 | 100 | 3.53 | 50 | 1.77 | 1.1 | 1750 | 600 | 1100 | 550 | 1500 | 1700 | 230 | |

VCB-150 | 150 | 5.3 | 75 | 2.65 | 1.1 | 1800 | 750 | 1200 | 550 | 1600 | 1800 | 250 | |

VCB-180 | 180 | 6.35 | 90 | 3.175 | 1.1 | 1900 | 800 | 1250 | 550 | 1800 | 1900 | 280 | |

VCB-300 | 300 | 10.6 | 150 | 5.3 | 1.1 | 2000 | 850 | 1350 | 550 | 1900 | 2050 | 380 | |

VCB-500 | 500 | 17.7 | 250 | 8.85 | 2.2 | 2400 | 950 | 1500 | 550 | 2080 | 2300 | 550 | |

VCB-1000 | 1000 | 35.3 | 500 | 17.7 | 4 | 2900 | 1300 | 1750 | 550 | 2200 | 2600 | 700 | |

VCB-1500 | 1500 | 53 | 750 | 26.5 | 4 | 3200 | 1400 | 2030 | 550 | 2580 | 2950 | 900 | |

VCB-2000 | 2000 | 70.6 | 1000 | 35.3 | 7.5 | 3550 | 1650 | 2300 | 550 | 2750 | 3200 | 1500 | |

VCB-2500 | 2500 | 88.25 | 1250 | 44.125 | 7.5 | 4000 | 1800 | 2450 | 550 | 2850 | 3500 | 1800 | |

VCB-3000 | 3000 | 106 | 1500 | 53 | 7.5 | 7.8 | 4400 | 1900 | 2600 | 550 | 3050 | 3600 | 2200 |

VCB-4000 | 4000 | 141.2 | 2000 | 70.6 | 11 | 7.8 | 4500 | 2000 | 2800 | 550 | 3500 | 4200 | 2800 |

*The data are estimated for reference only. (1L=0.0353cu.ft.; 1cu.ft.=28.3L)

No. 108, huishan road, huishan district, wuxi, jiangsu,china

+86 13771600869