loading

YK

RELA

YK

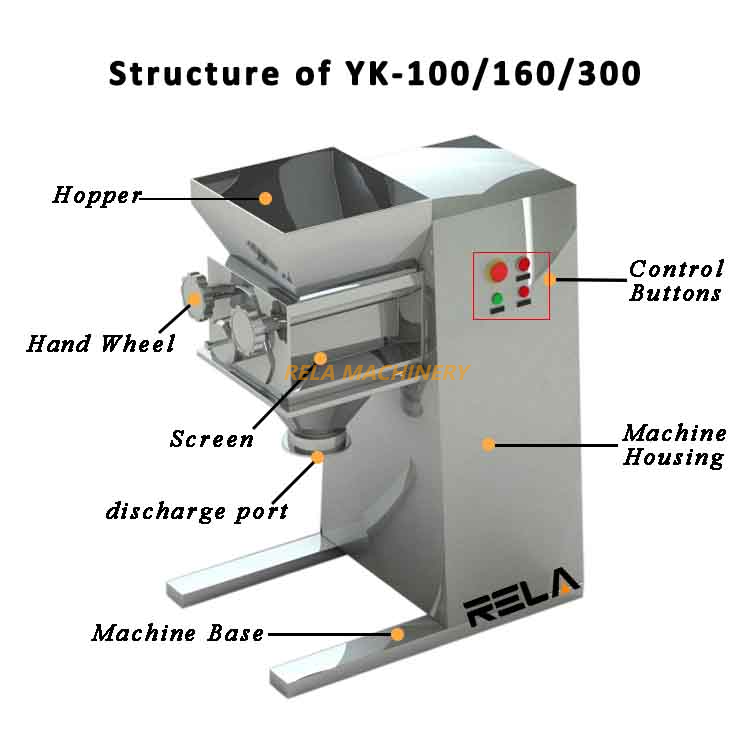

RELA Oscillating Granulator is a popular granulating machine used for size reduction or forming the required granule sizes from wet powder material, or for crushing dry powder caking and lump in the pharmaceutical, chemical and food industries. The oscillating granulators make the quality of granules better by facilitating their flowability and handling.

Working Principle:

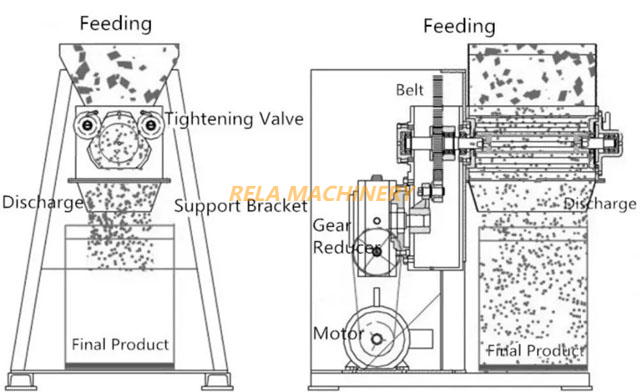

The Oscillating Granulator has one rotor, which oscillates on a horizontal axis. There is one screen of your required mesh size mounted at the bottom of the rotor which can be removed and remounted easily; its tension is also adjustable. Product is loaded from the top through the hopper, and falls on the rotor blade. The particles are broken down by a set the oscillating rotor as it moves back and forth. The sharp edges on the rotor, the oscillating movement of the rotor, and subsequent pressure of the product against the screen allows the size reduction of the granular material to take place as the material gets pushed through the screen mesh.

The driving mechanism is totally enclosed in the machine body and its lubrication system improves the lifetime of the mechanical components. These granulators are constructed with quality stainless steel to meet the GMP standard.

Technical Parameters:

Model | YK-60 | YK-100 | YK-160 | YK-300 |

Capacity (kg/h) | 20-50 | 30-200 | 100-300 | 150-800 |

Motor Power (KW) | 0.25 | 1.1 | 2.2 | 5.5 |

Rotor Speed (r/min) | 55 | 55 | 55 | 55 |

Rotation Range | 360° | 360° | 360° | 360° |

Rotor diameter(mm) | Ф60 | Ф100 | Ф160 | Ф300 |

Dimension (LxWxH) (mm) | 560*400*570 | 700×400×1050 | 1000×800×1300 | 1200*1000*1400 |

Weight (kg) | 55 | 200 | 350 | 500 |

RELA Oscillating Granulator is a popular granulating machine used for size reduction or forming the required granule sizes from wet powder material, or for crushing dry powder caking and lump in the pharmaceutical, chemical and food industries. The oscillating granulators make the quality of granules better by facilitating their flowability and handling.

Working Principle:

The Oscillating Granulator has one rotor, which oscillates on a horizontal axis. There is one screen of your required mesh size mounted at the bottom of the rotor which can be removed and remounted easily; its tension is also adjustable. Product is loaded from the top through the hopper, and falls on the rotor blade. The particles are broken down by a set the oscillating rotor as it moves back and forth. The sharp edges on the rotor, the oscillating movement of the rotor, and subsequent pressure of the product against the screen allows the size reduction of the granular material to take place as the material gets pushed through the screen mesh.

The driving mechanism is totally enclosed in the machine body and its lubrication system improves the lifetime of the mechanical components. These granulators are constructed with quality stainless steel to meet the GMP standard.

Technical Parameters:

Model | YK-60 | YK-100 | YK-160 | YK-300 |

Capacity (kg/h) | 20-50 | 30-200 | 100-300 | 150-800 |

Motor Power (KW) | 0.25 | 1.1 | 2.2 | 5.5 |

Rotor Speed (r/min) | 55 | 55 | 55 | 55 |

Rotation Range | 360° | 360° | 360° | 360° |

Rotor diameter(mm) | Ф60 | Ф100 | Ф160 | Ф300 |

Dimension (LxWxH) (mm) | 560*400*570 | 700×400×1050 | 1000×800×1300 | 1200*1000*1400 |

Weight (kg) | 55 | 200 | 350 | 500 |

No. 108, huishan road, huishan district, wuxi, jiangsu,china

+86 13771600869