loading

RXH

RELA

RXH

Drying and extracting water or solvents from humid powder or small granule products.

The product is put on the trays and dried batch by batch.

Heating source: Eletricity or Steam.

Hot air is cuiculated in the drying chamber, saving energy.

Application:

RELA RXH Tray Dryer Oven is a static dryer with hot-air recycle. It is suitable to dry kinds of material (powder, granule, slice, bottle, etc.) in Pharmaceutical Industry, Foodstuff Industry, Spice Industry, Chemical Industry, etc.

Working Principle:

RXH Tray Dryer is equipped with axial flow blower fan, which is low-noise and high temperature resistant. The drying temperature is controlled automatically. After the material being dried is loaded into the trays, start the electric heating or get through steam. Under the blowing of blower fan, the hot air recycles in the oven. As the recycle system is enclosed, the drying efficiency increases to 35%-45% from traditional 3-7%. So it can save much energy. ,

Features:

Heat Source: electricity or steam, or both.

Commonly Drying Temperature: steam-50-130°; electricity-50-300°.

mmonly steam pressure: 0.2-0.8 Mpa.

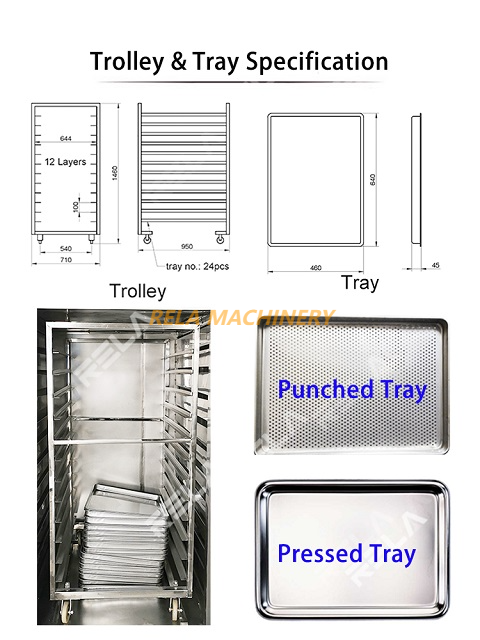

The standard size of tray is 480x640x45mm

Contact part in SS304 or SS316L

Temperature is detected by a sensor PT-100 and controlled automatically.

PLC & HMI is available; simple printer is available.

Technical Parameter:

Type | capacity (Kg/batch) | Blower Power (KW) | Steam Consumed (Kg/h) | Heat radiating area (m2) | Air flow (m3/h) | Temp. Difference | Tray No. | Trolley No. | Overall dimension (L×W×H)mm |

RXH-7-C | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1 | 1400×1200×2000 |

RXH-14-C | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2 | 2300×1200×2000 |

RXH-27-C | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 4 | 2300×2200×2000 |

RXH-41-C | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 6 | 2300×3200×2000 |

RXH-54-C | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 8 | 4460×2200×2290 |

Application:

RELA RXH Tray Dryer Oven is a static dryer with hot-air recycle. It is suitable to dry kinds of material (powder, granule, slice, bottle, etc.) in Pharmaceutical Industry, Foodstuff Industry, Spice Industry, Chemical Industry, etc.

Working Principle:

RXH Tray Dryer is equipped with axial flow blower fan, which is low-noise and high temperature resistant. The drying temperature is controlled automatically. After the material being dried is loaded into the trays, start the electric heating or get through steam. Under the blowing of blower fan, the hot air recycles in the oven. As the recycle system is enclosed, the drying efficiency increases to 35%-45% from traditional 3-7%. So it can save much energy. ,

Features:

Heat Source: electricity or steam, or both.

Commonly Drying Temperature: steam-50-130°; electricity-50-300°.

mmonly steam pressure: 0.2-0.8 Mpa.

The standard size of tray is 480x640x45mm

Contact part in SS304 or SS316L

Temperature is detected by a sensor PT-100 and controlled automatically.

PLC & HMI is available; simple printer is available.

Technical Parameter:

Type | capacity (Kg/batch) | Blower Power (KW) | Steam Consumed (Kg/h) | Heat radiating area (m2) | Air flow (m3/h) | Temp. Difference | Tray No. | Trolley No. | Overall dimension (L×W×H)mm |

RXH-7-C | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1 | 1400×1200×2000 |

RXH-14-C | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2 | 2300×1200×2000 |

RXH-27-C | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 4 | 2300×2200×2000 |

RXH-41-C | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 6 | 2300×3200×2000 |

RXH-54-C | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 8 | 4460×2200×2290 |

No. 108, huishan road, huishan district, wuxi, jiangsu,china

+86 13771600869